Creating high-quality custom hats involves more than just picking a design and slapping a logo on it. It’s a meticulous process that requires attention to detail, creativity, and skilled craftsmanship to bring your brand’s vision to life. In this article, we take you behind the scenes of our custom hat production process, from initial design to final quality control. You’ll see exactly what goes into making the perfect promotional hat that proudly showcases your brand.

Step 1: Concept and Design – Bringing Your Vision to Life

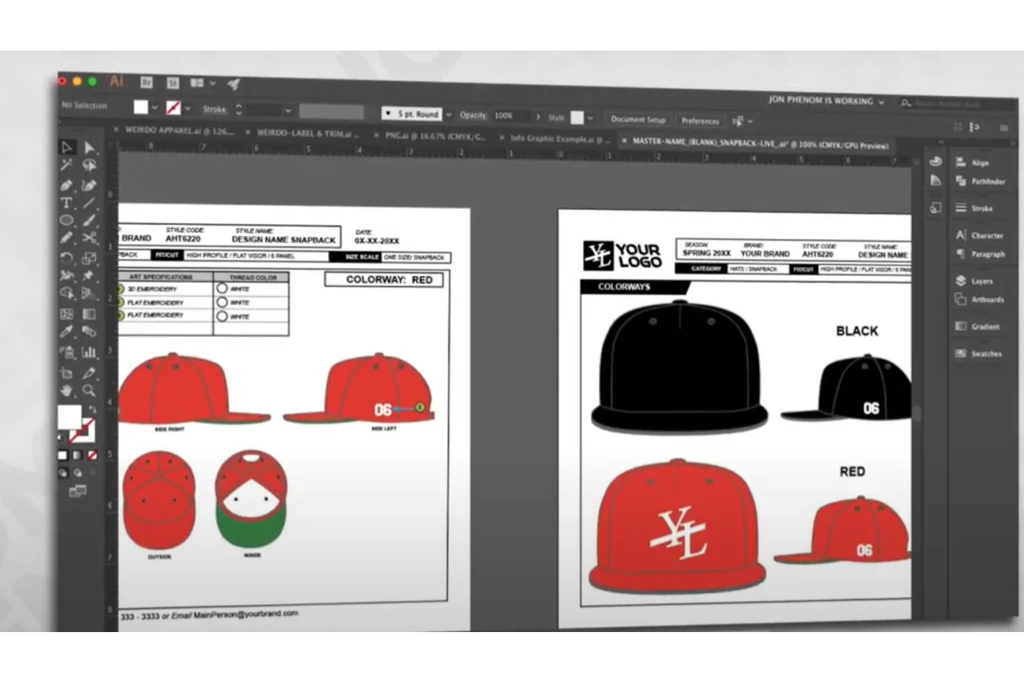

Every custom hat begins with an idea. Our design process starts by collaborating closely with you to understand your brand’s personality, goals, and preferences. Whether you have a rough sketch or a fully developed concept, we take your input and refine it to ensure that it fits the unique shape and style of your chosen hat.

What Happens in This Step:

- Brand Consultation: We gather key details about your brand, color schemes, logo placement, and the purpose of the custom hats (corporate events, giveaways, etc.).

- Sketching and Digital Mockups: Our in-house design team creates initial sketches and digital mockups of your hat. This gives you a clear vision of how the finished product will look, allowing you to approve or request changes.

- Style Selection: You choose from various hat styles—like snapbacks, trucker hats, beanies, or dad hats—to match your brand’s image and the occasion.

Step 2: Material Selection – Choosing the Perfect Fabric

Once the design is finalized, we move on to selecting the best materials for your hats. The quality of the fabric directly affects the comfort, durability, and overall appearance of the final product. Depending on your needs, we offer a range of fabrics such as cotton, polyester, wool, or a blend of materials to ensure your hats meet both aesthetic and functional requirements.

What Happens in This Step:

- Fabric Choices: We offer high-quality, breathable materials like cotton and polyester, as well as specialty fabrics for premium hats.

- Matching Brand Colors: Our team ensures that the fabric colors match your brand’s specifications, creating a cohesive look.

- Material Testing: Each fabric is tested for durability, color fastness, and comfort to ensure that the hat will last long and look great.

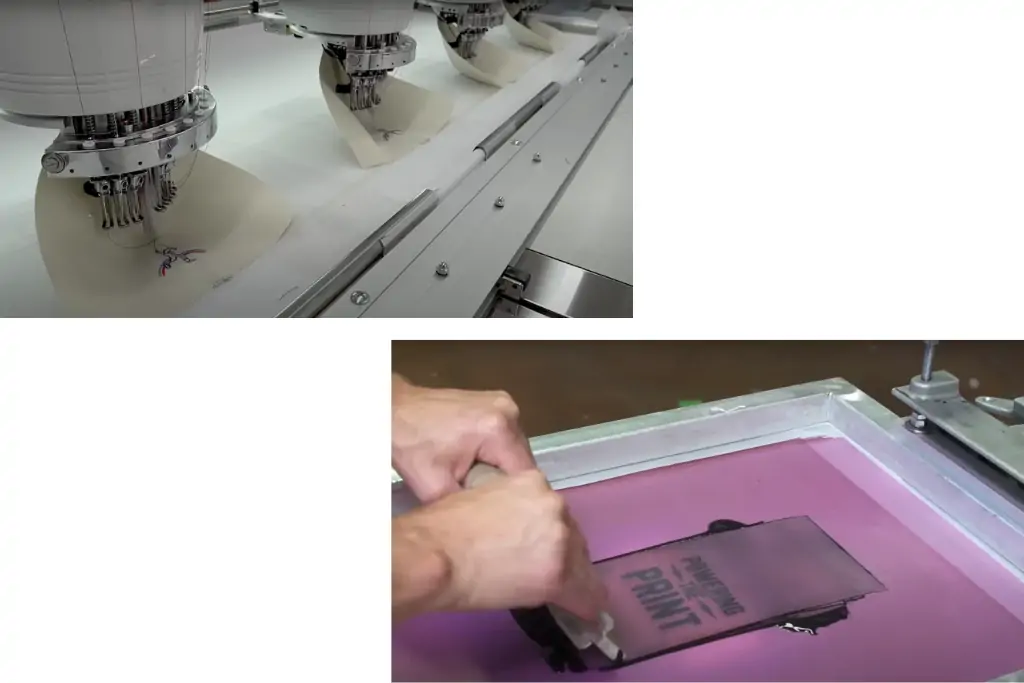

Step 3: Logo Application – Precision and Craftsmanship

The logo is the heart of your custom hat design. It’s the visual representation of your brand, and we treat it with the utmost care. There are various techniques for applying logos to hats, each offering unique advantages depending on the look you want.

Techniques We Use:

- Embroidery: For a classic, professional look, embroidery is one of the most popular options. Your logo is stitched directly into the fabric, offering a textured, durable finish that stands out.

- Screen Printing: For bold, graphic designs with lots of colors, screen printing applies ink directly to the hat’s surface, ensuring vibrant colors and clear lines.

- Heat Transfer: This technique uses heat to apply your logo to the hat, ensuring sharp, vivid images. It’s ideal for more intricate designs or detailed logos.

What Happens in This Step:

- Logo Placement: We offer several placement options, such as the front panel, sides, or even under the brim, to give you flexibility and visibility.

- Logo Size Adjustments: Depending on the hat style, our team carefully adjusts the size and positioning of your logo for maximum impact.

- Color Matching: Our embroidery or printing machines are calibrated to match your brand’s colors, ensuring consistency across all custom hats.

Step 4: Production – Crafting Each Hat with Precision

With the design and logo confirmed, we move into the production phase. This is where the hats come to life through a combination of technology and skilled craftsmanship. Our state-of-the-art machinery ensures that each hat is made to exact specifications, while our team of experts oversees every step to maintain high-quality standards.

What Happens in This Step:

- Cutting and Stitching: Fabric is precisely cut to match the shape of the hat, then stitched together by skilled workers to create the base of your custom hat.

- Logo Application: Whether through embroidery or printing, the logo is applied to the hat with meticulous attention to detail.

- Shaping: The hat is carefully molded to ensure the right fit and structure, whether it’s a fitted cap, a snapback, or a beanie.

Step 5: Quality Control – Ensuring Perfection

Before your custom hats are shipped, they undergo a rigorous quality control process. We inspect every detail—from the stitching to the logo application and overall construction—to ensure the final product meets our high standards and your expectations.

What Happens in This Step:

- Visual Inspection: Our team checks each hat for any imperfections, such as loose threads, inconsistent stitching, or misaligned logos.

- Fit and Comfort Testing: We ensure that every hat maintains its shape and provides a comfortable fit, adjusting as needed.

- Final Touches: Any final adjustments are made, such as trimming excess fabric, cleaning any residual marks, and ensuring that logos are crisp and clean.

Step 6: Packaging and Shipping – Delivering Your Custom Hats

Once the hats pass our quality control checks, they are ready to be packed and shipped to your desired location. We take care in packaging the hats to ensure they arrive in pristine condition. Depending on your needs, we can also arrange bulk shipping for events or promotional giveaways.

What Happens in This Step:

- Secure Packaging: Each hat is carefully packaged to prevent damage during transit.

- Bulk Shipping: For larger orders, we offer bulk shipping to save costs and ensure timely delivery to corporate events or trade shows.

- Delivery Tracking: We provide tracking information so you can monitor your shipment and know exactly when to expect your custom hats.

Behind Every Custom Hat is a Story of Craftsmanship

Every custom hat we produce is more than just a promotional item—it’s a reflection of your brand’s identity. From concept to completion, we take pride in delivering high-quality, carefully crafted hats that make a lasting impression. Whether you’re gearing up for a corporate event, trade show, or giveaway, our team ensures that every detail is perfect.

By taking you behind the scenes, we hope to showcase the care, craftsmanship, and precision that goes into creating each and every custom hat. When you work with us, you’re not just getting a product—you’re investing in a powerful marketing tool that represents your brand.

Conclusion: Why Quality Matters in Custom Hat Production

From design to delivery, our goal is to make sure that your custom hats are of the highest quality. We believe that attention to detail, careful craftsmanship, and a deep understanding of your brand are what set our custom hats apart. As a result, you get more than just a hat—you get a piece of your brand’s identity, ready to be worn and displayed with pride.

The next time you need custom hats for a corporate promotion, remember the care and effort that goes into each step of the production process. We are proud to bring your brand to life, one hat at a time.